Gannet Technical Services offers a complete control system design service for technically complex industrial and research applications. In addition to industrial and mineral processing applications, the company has developed considerable experience in the areas of low temperature cryogenics and superconducting magnets. Our approach to a design is to develop and understanding of the machine and process before discussing the specification with the client.

We offer a full design service including:Although we can work with most platforms, we have extensive experience with the following technologies:.

SCADA and PLC software for conducting a test on a length of superconducting bus bar cooled by a helium refrigerator. A particular requirement of the software was to have the means to make quick modifications both for changes in the experimental procedure and to match hardware changes in the control system. The software included a utility which allows control loops, physical output addresses and control patterns for the “state machine” to be modified without the need to edit the PLC programme. A major part of the experiment was for control devices to be controlled by more than one loop simultaneously with “bumpless” transfer of control between the loops. The software consists of four components:

The resulting software suite was supplied and bench tested for the specific experiment designed by the client. In addition to this it also provides a platform for the rapid development of similar programmes to control other experiments based around the Siemens S7 PLC.

This was automated test rig for testing relay based personnel protection systems for the new synchrotron which has been built at the Diamond Light Project. The task was to develop a system for testing the rack based personnel safety systems. There are a large number of these being built, each using a common rack based design but differing in their wiring so that each requires a unique test sequence. The first stage of the project was a detailed design study to develop a specification for the client to put out to tender. Having won the tender, the test hardware was designed and subcontracted. The software was developed and finally tested on two of the protection racks which had already been completed.

The first programme supplied is a stand alone utility for the designer of the personnel protection racks. This reads a node list generated from the designers CAD drawings for the rack, checks it against the standard rules for the racks design and produces an output file ready for the test.

The test equipment itself was based on a Wago I/O modules controlled directly from a PC. The inputs to and the outputs from the racks under test are connected to the test rig. The control programme reads the design file generated by utility described above and works out a suitable test procedure for the rack. The PC then generates bit patterns to fed to the rack under test and monitors the results.

In addition to the original requirement for an efficient maintenance tool, the resulting test system helps find errors both in the original design and in the physical wiring for each protection system as it designed and built, greatly reducing the overall implementation cost. The During the course of the project, the customer ordered a complete 2nd set of hardware and software for a neighboring synchrotron.

Gannet was responsible for two major projects to control kaolin separation plants using superconducting magnets. These projects were for complete controls systems including both software and hardware. The separators consisted not only of the cryomagnet, its power supply and its instrumentation, they also included the mineral processing components – automatic valves, filters etc. The software generally included substantial control and monitoring of the customer’s plant either side of the separator – pumps, control valves, flow transmitters, densitometers etc

The projects would commence with extensive discussions with the customer about the extent of supply and, separately, the extent of the control system. The plants would be built and tested dry at the manufacturing site before installation and commissioning at the final location. Gannet was responsible for the design of the complete control system from the initial post sale discussions to the final commissioning.

Design of control system and PLC software for superconducting magnet ‘outsert’ for ‘hybrid’ magnet installed in the High Fields Magnet Laboratory in Grenoble. As a prototype system the design had to anticipate changes in the control requirement during commissioning. The result had flexibility built into both hardware and software to allow for the easy addition or modification of devices. The PLC programme included an Excel spreadsheet which allowed settings to be changed, control and measurement devices to be added and control sequences to be modified very simply. The result was that changes which would normally have required a full time software engineer and extensive delays could be implemented quickly, with very little downtime and often, remotely.

In June 1997 Gannet Technical Systems was started with a view to providing innovative & effective control solutions for industry. The company was established in West London in 1997 and moved to its current location in Nottingham in August 2006. Our address is:

Gannet Technical ServicesTo contact us by e-mail, please use the reply form above.

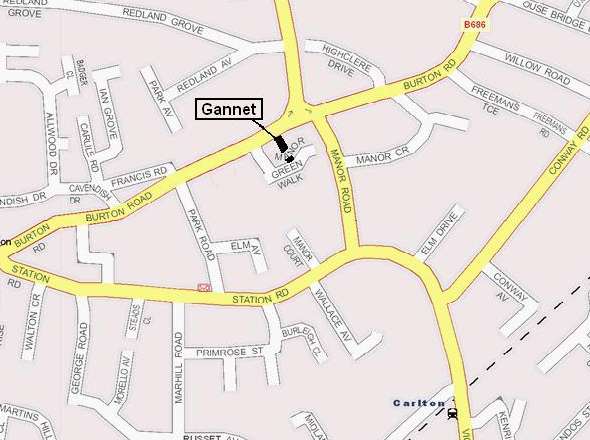

We are easily accessible from M1 and A1, the following maps will help you find us.

Gannet Ltd. trading as Gannet Technical Services. Registered in England number 3375325. Directors - S.G. Fanshawe, Mrs. D.S. Fanshawe./font>